The Tenth Exhibition Photonics 2015, a jubilee event and largest domestic show of laser hardware, optical and related technologies, opened in Moscow on March 16.

Laser Center products were put on display at a large stand with industrial laser demonstration zones and an area offering professional consultations. Our stand featured technologies and equipment for laser marking and engraving – MiniMarker2 and TurboMarker systems of various modifications, precision laser cutting - RX-150, and laser precision and seam welding – Photon-Compact, as well as brand new creations of Laser Center Company, the object recognition and processing field adjustment marking system Video Compas, and a new system for laser processing of electronic materials MicroSET.

Modern lasers provide remarkably high levels of stability in spatial and temporal single-mode radiation parameters in a broad range of beam parametric variations. These properties and a possibility of high precision (several microns) and rapid (10 to 20 meters per second) control of focused radiation trajectory create new opportunities for the development of technologies based on control over thermal fields in material. Solutions and hardware for cutting sheet materials and alloys by lower-power pulsed lasers, 3-dimensional metal engraving and ultra-fast laser drilling of metals and alloys have been developed on the basis of this principle just recently.

The principle of high precision control of thermal fields in material offers special advantages in the development of technologies and engineering equipment for laser treatment of electronic materials. The electronic industry uses rather “exotic” materials from the laser treatment point of view, among them semiconductor poly and mono-crystals (silicon, gallium arsenide, etc), ceramic materials based on aluminum and silicon oxides, nitrides, carbides, precious metals and alloys. Thermal gradients that unavoidably occur in any laser technological operation are not good for these materials. Besides, the electronic industry frequently requires bimaterials, such as components of alundum ceramics PCBs coated with copper. The aforementioned tasks cannot be solved by regular methods of laser treatment because the thermal fields created by such methods can lead to deformations and defects and the treatment of multi-component materials will be practically impossible due to the damage done to one layer during the treatment of another.

The method of precision thermal field control in laser treatment of materials employed by the MicroSET system of Laser Center Company is capable of accomplishing a variety of engineering tasks in the field of dimensional laser treatment of electronic materials. Technologies have been developed for defect-free laser cutting of polycrystalline silicon and other semiconductor materials, cutting of ceramic materials, ultra-fast drilling of ceramic and other materials, the forming of shape-holes and meso-structures, de-metallization and production of ceramic PCBs, creation of high-resolution topologies and line targets, resistor adjustment, etc. The method of precision control and formation of thermal fields with set characteristics are offering practically unlimited opportunities for the development of laser technological operations for material treatment.

A new series of TurboMarker equipment was demonstrated at the exhibition with laser emitters of various capacities, which revealed the entire potential of this equipment, including ultra-fast laser marking, high metal engraving and treatment of various materials and types of surface.

Laser engravers Trotec demonstrated by our Austrian partner are a type of hardware even the smallest company can afford. The machine tools are universal and provide high quality treatment (cutting and engraving) of many popular materials, such as plastic, wood, Plexiglas, leather and cardboard.

Deputy Chairman of the State Duma Industry Committee Pavel Sergeyevich Dorokhin, Vice-President of the Chamber of Commerce and Industry of Russia Dmitry Nikolayevich Kurochkin and other officials visited the Laser Center stand on March 16, 2015.

The exhibition was accompanied by a vast business program. The Photonics technological platform was discussed in detail on the first day of the show, under the chairmanship of K.A. Tarabrin, Department Director at the Russian Industry and Trade Ministry.

Specialists of our company gave numerous consultations and held negotiations on mutually advantageous partnership with Russian and foreign companies on the sidelines of Photonics 2015 exhibition.

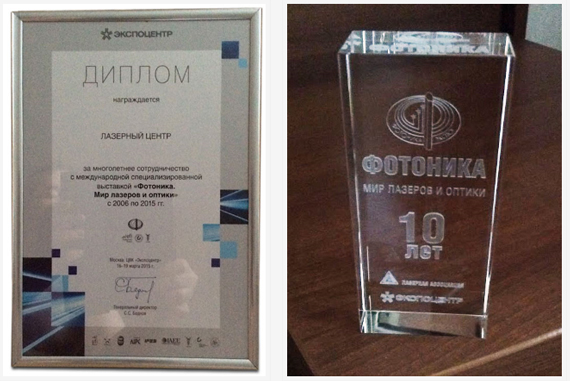

Our long-lasting and fruitful cooperation with the International Specialized Exhibition, Photonics World of Lasers and Optics, marked its tenth anniversary in 2015. Laser Center Company received a commemorative diploma and a present from the exhibition organizers on the opening day.

Source: http://www.newlaser.ru/about/expo2015/photonics.php